Designs for a “robot archeologist” and the “solar roller” — a power station on wheels — are two of many promising innovations emerging from the ANU Engineering Capstone initiative in 2021.

Sixteen semester 2 projects are now underway, with seven recently-completed projects having been unveiled at the Capstone showcase that rounded out Semester 1.

Capstone comprises an undergraduate and a masters engineering course aiming to deliver value to academics and industry clients following a systems design framework. Capstone students develop conceptual designs, sub-system requirements, evaluate risk as well as manage quantitative trade-off analyses.

The 20 July Capstone showcase was held in the Hanna Neumann Building, attended by nearly 100 people, including student presenters, academics, and industry leaders. Undergraduate course convenor Dr Catherine Galvin said she felt fortunate to be able to hold the event, given the fast-changing situation in Australia. Just a few weeks later, a COVID-19 lockdown would be announced in the Australian Capital Territory (ACT).

“The fact that the event was sold out, despite the changing COVID situation is a testament to the interest in the programme by the broader engineering community,” Galvin said.

In attendance were potential industry clients for future Capstone projects, and graduate course convenor Dr Nicolo Malagutti addressed them directly in his introductory remarks.

“Imagine our students as a little group of consultants to meet your requirements and give you something you need,” he said.

Malagutti explained that clients do not need to have engineering expertise, citing a farmer who owns a nearby egg farm. “The farmer knew nothing about robotics,” Malagutti said. “They could tell us everything about how they wanted their eggs sorted, but they knew nothing about how to achieve it. Our engineering students planned, designed and delivered them a good product.”

A primary goal of Capstone is to “provide a foundation for ANU and its students to connect with a local network of potential collaboration stakeholders and employers,” Malagutti said. Participating students expressed an enthusiasm for solving interesting real-world problems and contributing to society.

Designing a robot archeologist

Zhiyuan Li presented on behalf of a team whose client was Dr Tim Denham of the ANU School of Archaeology. Denham was seeking an automated method for extracting organic materials from ancient pottery sherds.

The existing approach begins with a Micro-CT scan of the pottery sherds. Archeologists are guided by images from the scan as they unearth organic samples by hand, which can be time-consuming and imprecise.

“We have helped our client design a computer-controlled version with a robot doing the job,” Li said. “The samples are sequentially put into glass cuvettes for analysis.”

Fellow designer Duy Le said, “All members of the team came from an engineering background and no one knew anything about archaeology before. The project was an interesting engineering design problem and it was quite challenging. That’s why we chose to take on this project.”

The resulting “robot archeologist” design proposal is for a machine that can locate and sample organic remains, with microdrilling guided by 3D images.

The team, which also included Ying Men and Yuchen Lei, created animation to illusrate their design. They hope their work will lead to a commercial product that becomes widely used in archeological studies.

Charting the future of solar energy

Nihal Abdul Hameed and Amit Patankar presented for a project called Techno-Economic Analysis of PV-CSP Hybrid Power Plant.

Patankar told audience members that there is a “very strong push for renewable energy all over the world, especially solar energy because of how abundant it is and the falling cost of solar cells.”

To facilitate this transition, the team set out to solve a problem that has hindered solar energy up till now. “Solar energy reaches its peak in the afternoon when demand is down,” Patankar explained. “In the evening, solar energy falls and demand shoots up.”

A solution would need to include the storage of energy generated during the day so that it can be delivered later during peak demand.

Concentrated solar power (CSP), which generates power with mirrors or lenses that concentrate sunlight onto a receiver, was a good candidate because it can be linked with thermal storage. But CSP is very expensive.

“So, in order to make the energy produced cost efficient, we introduced photovoltaics (PV) into the system,” Hameed explained.

Solar PV is a more affordable technology used in rooftop solar panels. PV produces electricity directly from sunlight, whereas CSP uses the sun’s energy to produce heat from which electricity is then generated.

The team proposed a hybrid plant with PV supplying energy to meet daytime demand, while CSP gathered and stored energy for later. “The heat stored would run a turbine and produce electricity in the evening, or, when the PV is not producing electricity due to cloudy weather,” Hameed said.

The team, which also included Chamrongrath Cheath, Chithral Kodagoda, Naman Jain, and Varad Kareker, used computer modeling to find the right balance between PV and CSP power to minimise the commissioning cost of a hybrid plant while maximising its profitability.

The solar plant “should not send out electricity at all times,” Hameed said. “At certain points, the market electricity price would be low or negative. If we store the energy produced at that time and dispatch it when the market price is high, it would be more beneficial.”

The team’s client was Dr John Pye, an Associate professor in CECS and part of the Solar thermal research group. Hameed credits Pye with inspiring his team by showing them how and why solar technology is being implemented around the world. “The fact that the work we are doing is going to be implemented in real life gave us a huge motivation,” Hameed said.

A second team investigating solar power was represented at the Capstone showcase by Rand Hassan and Fatima Hamid.

Hassan began by explaining that “the transport sector contributes more than 60% of the total greenhouse gas emissions in the ACT.”

The ACT government plans to change this by supporting zero emissions electric vehicles.

“One of the main driving forces behind the deficiency in using electric vehicles is the lack of high-speed charging facilities,” Hamid said.

So, the team looked at the feasibility of a neighbourhood battery system to support increased electric vehicle usage using clean energy sources, selecting the Canberra suburb of Franklin as a study case.

The solar energy company Reposit Power provided them with data from 100 houses in Franklin that have rooftop solar panels. The team found that, in addition to powering the homes beneath them, the PV panels on these 100 homes can produce up to 90% of energy required by 2,444 electric vehicles, one for every household in Franklin.

The team, which also included Fengjiao Wang, Kanij Fatema, Karthik Mynampati, Keni An, and Rand Ababneh, ran simulations to calculate that the total energy required by 2,444 electric cars could be supplied by 7 tesla power pack batteries with a size of 223kWh.

“I was so excited and very keen to introduce our project findings to the industry,” Hamid said.

After the event, the students were approached by audience members. This was “a great chance for us to discuss our findings with industry experts,” she said.

Make way for the Solar Roller —————————–

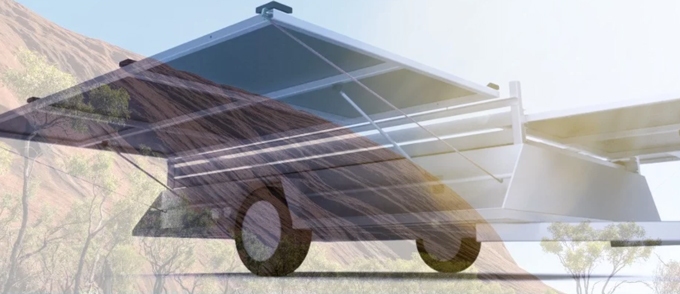

Priya Guha leads a Semester 2 undergraduate team developing a trailer fitted with solar panels — nicknamed the “Solar Roller” — to bring clean energy to communities and activities in regional and remote Australia.

Guha explained that the Mobile Solar Trailer will be “transportable across locations on Country and moved around as needed. Mobility and durability for the trailer are a key focus for our users and for the context of this project.”

The concept for the Mobile Solar Trailer was developed by Engineers Without Borders (EWB) Australia and the Bushlight program of Centre for Appropriate Technology (CfAT). The ANU School of Engineering has been assisting with the prototyping for the trailer. The team has fortnightly meetings with client Angus Mitchell of EWB, and sometimes more if needed.

The Solar Roller team also includes Matthew Duan, David Nguyen, Harmanpreet Kaur, Meghana Sayyaparaju, and Qinying Wan. Guha says the team members’ unique backgrounds offer opportunities to learn from one another.

The project requires a number of specializations for solar, electrical, and mechanical components. “We split the allocation of tasks based on strengths and experiences of our team, such as five of us having an electronics background and another with a renewable energy background,” Guha said.

Due to the ACT public health lockdown, the team is looking into using software to model their designs. Physical prototyping had been the original plan. Research into inverters was delayed partly due to the lockdown but “other than that, most of our other deliverables are still able to be met”, Guha said.

Semester 2 projects selected virtually ————————————–

Project selection for the Semester 2 graduate course was conducted virtually with many students participating from other parts of Australia and overseas. Prospective clients provided a short summary of their projects, followed by a question-and-answer session. Students then self-selected into teams.

Galvin described a similar process for the undergraduate course. “We used Zoom and its breakout rooms for the selection evening,” she said. “Each client was in a breakout room and students were able to move between the rooms, meet the clients and ask questions about the project.”

In the past, the selection process had been in person, but Galvin said the virtual setting was not a dampener. “There was still a great deal of excitement for both students and clients.”

The convenors’ hope that the Semester 1 showcase would yield new clients for Semester 2 was well founded. Despite an unusually large student enrollment, “We had more projects than students, which is what I wanted to happen,” Galvin said.

There are 13 undergraduate projects for Semester 2, and 3 graduate projects. The interdisciplinary range is even greater than before, with a continued focus on renewable energy.

In addition to the “Solar Roller,” Capstone’s undergraduate projects for Semester 2 include a solar oven, a breath test for type 1 diabetics, and waste bins capable of signaling the level to which they are filled.

The Knee Robot project builds upon a design and prototype developed by Capstone students in Semester 1 for a clamp with integrated sensors to be used during knee replacement surgery.

The graduate level projects are (1) automatic navigation of unmanned watercraft, (2) modelling and simulation for clean, all-electric suburbs in the ACT, and (3) renewable hydrogen fuel for industrial processing.

Several of the projects have clients that require non-disclosure agreements (NDAs). Malagutti said this could signify clients are seeing the Capstone process as more than just an exercise.

“Students are being potentially granted access to commercial-in-confidence company information and/or anticipated to produce outputs that have commercial value and are therefore worth owning/protecting,” he said.

In 2022 ANU Capstone will be a full-year course, providing students and clients more time to develop their projects and present innovative, technology-based solutions to real-world problems.